Nearly 50 years ago, SIMCO Drilling Equipment, Inc. produced their first all-hydraulic top head drive system—and a better way to produce an auger-drilled hole faster and more efficiently. Today’s SIMCO is still innovating and producing some of the most reliable and versatile drilling rigs in the industry.

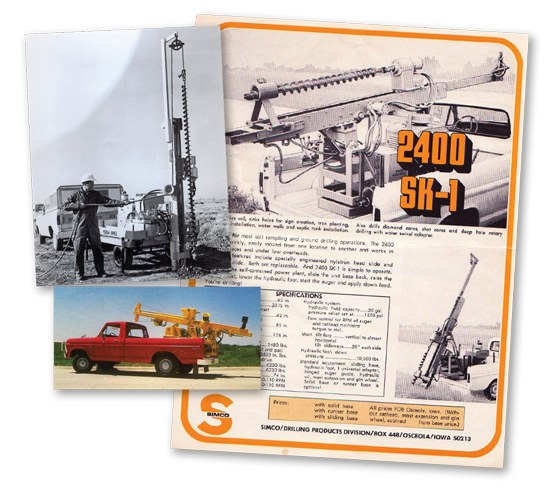

The skid-mounted 2400SK was one of only a handful of products shipped from SIMCO’s Iowa factory back in 1971. It was a ‘no-frills’ earth auger drill, powered by a 24 H.P. gas engine, with a whopping 291 ft. lbs. of torque. But the 2400SK was simple to operate, easy and inexpensive to maintain and service, and was able to perform a variety of drilling tasks: auger soil sampling, signpost hole drilling, septic tank perc tests, and ground rod installations. Today, this work horse of a rig has become so versatile that it still handles these jobs and so much more.

Now sporting a 56+ H.P. Tier 4 Final diesel engine and three independent hydraulic circuits, the 2400 can produce up to 2000 ft. lbs. of torque. When we talk about versatility, there are many options:

- pair that power with an automatic hammer or cathead for SPT soil sampling

- add a hydraulic sinker drill and an air compressor to build a 2400 DRILLTEAM for water or gas line leak pinpointing

- install a hydraulic probe hammer or change the drill head to a high-speed version for coring

- hook up a proper size mud pump and you get a mud rotary, water well rig

The SIMCO 2400 isn’t the only versatile powerhouse offered. In 1976, SIMCO pioneered the use of a hydrostatic transmission for the rotary drillhead on the 2800 HS. The variable volume piston pump and motor combination can create hydraulic pressures up to 5000 psi. Now the driller has fingertip control of the infinitely variable rotation of the tooling. The 2800’s hydrostatic system was so efficient the rig could easily be powered with a smaller H.P. engine, saving money, weight, and fuel.

Early versions of the 2800 had a drillhead rated at 1500 ft. lbs. and 0-150 RPM, but current models can now deliver up to 7500 ft. lbs. and produce an infinite range of speed up to 750 RPM. The principal features of the 2800 haven’t changed over the decades, performance, efficiency, and range of service certainly has.

These two SIMCO geotechnical drill rigs have set the standard for all-hydraulic, top head drive machines, and SIMCO’s reputation for top-grade engineering, craftsmanship, and quality continues to raise the bar. When the experience and knowledge of the SIMCO parts and service department is added to the incredible warranty included in each purchase, it’s no surprise that SIMCO Drilling Equipment, Inc. has maintained its leadership position in the industry.