Versatility and reliability are essential when it comes to drilling, and SIMCO’s 2800 drilling rig has been held as the standard in the drilling industry for years. Rugged and compact, this tough geotechnical drilling rig’s variable speed drill head is just one of the superstar components of the 2800. It gives you torque when you need it and maximum RPM efficiency, but there are many other important benefits for you, your customers, and your business.

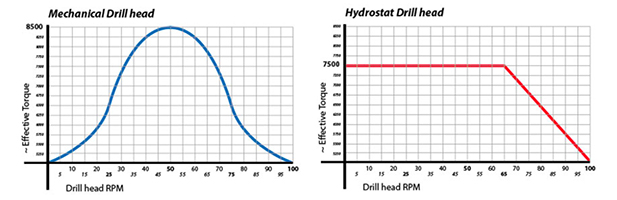

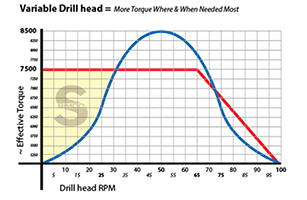

By keeping the torque constant at any speed, the variable speed drill head on the 2800 lets you move smoothly through the layers of your geotechnical drilling site. You get infinitely adjustable rotation control in all speed ranges, allowing auger start up at maximum torque and lower RPMs. The broad torque curve of hydrostatic rotation lets you control the power when you need it most.

Another great feature of the variable speed drill head is its efficient use of horsepower. As the torque requirement increases, the drill head will automatically slow down. You get top geotechnical drilling power without pushing the engine’s horsepower capabilities and putting unnecessary stress on your drill rig. Combined with the movement and flexibility of a floating drill head, the variable speed guards against thread seizing. You get the confidence of being able to make and break drill rod connections without having to battle thread galling. This floating characteristic of the variable speed drill head also eases wear on your rig by acting as a shock absorber during down the hole hammer drilling.

For more than fifty years, SIMCO has held an industry reputation for offering features to help you get the most out of your drilling equipment. The 2800 geotechnical drilling rig with the floating, variable speed drill head is the top of the line when it comes to efficiency, safety, and the power to get the job done right.