Hard rock drilling presents its own unique challenges. One way to get the most out of your SIMCO 2800 or 7000 drilling system is by pairing it with a heavy-duty auxiliary air compressor. The versatility of SIMCO equipment allows you to meet hard rock drilling needs, putting the torque and drilling pressure where it’s needed most.

The need for auxiliary air compressors will vary depending on the job. No two jobs are the same and will require unique air control for each drilling operation. The makeup of the hole you’re drilling will determine whether one air compressor will get the work done or if multiple pressures and flows are needed, requiring more than one unit.

On any hard rock drilling operation, depth and diameter have to be taken into consideration when determining the air pressure needed to clear out cuttings. Your air pressure needs also depend on the type of drilling being done. High pressure air of 200 psi or above is necessary when running hammer drills, cluster drills, or rotary drills through hard rock. Air pressure needs are typically lower with rotary drilling, and a large air volume, low-pressure compressor would most likely do the job. When other drilling techniques call for high pressure, you may need to consider a dual-pressure auxiliary air compressor for versatility.

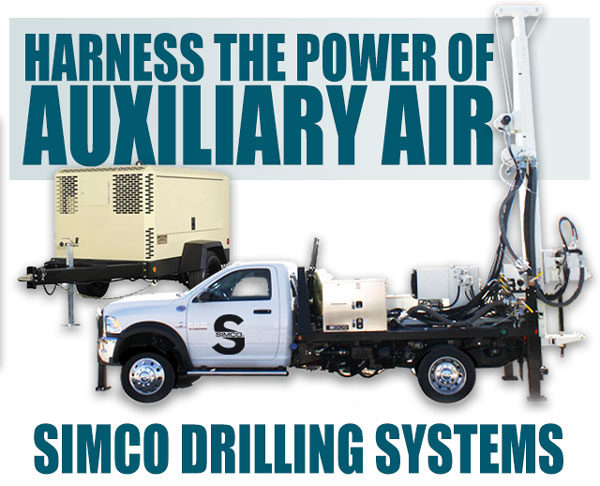

No matter if your hard rock drilling needs call for a low pressure auxiliary air compressor or high pressure working air, SIMCO drilling rigs like the SIMCO 2800 or the SIMCO 7000 can get the job done. Large auxiliary air compressors come separate on a trailer and are compatible with SIMCO models. This provides your operation the versatility to complete hard rock drilling jobs no matter the environment you find yourself in.